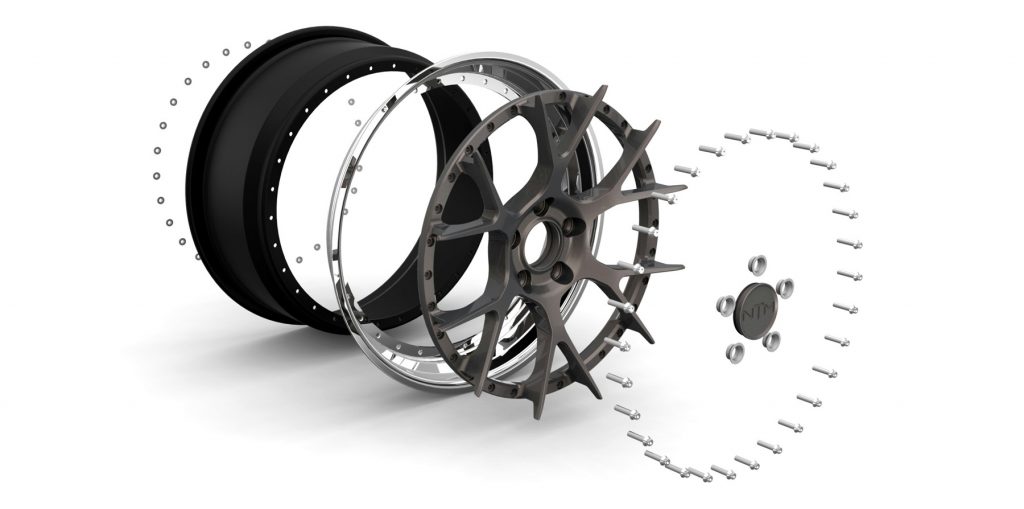

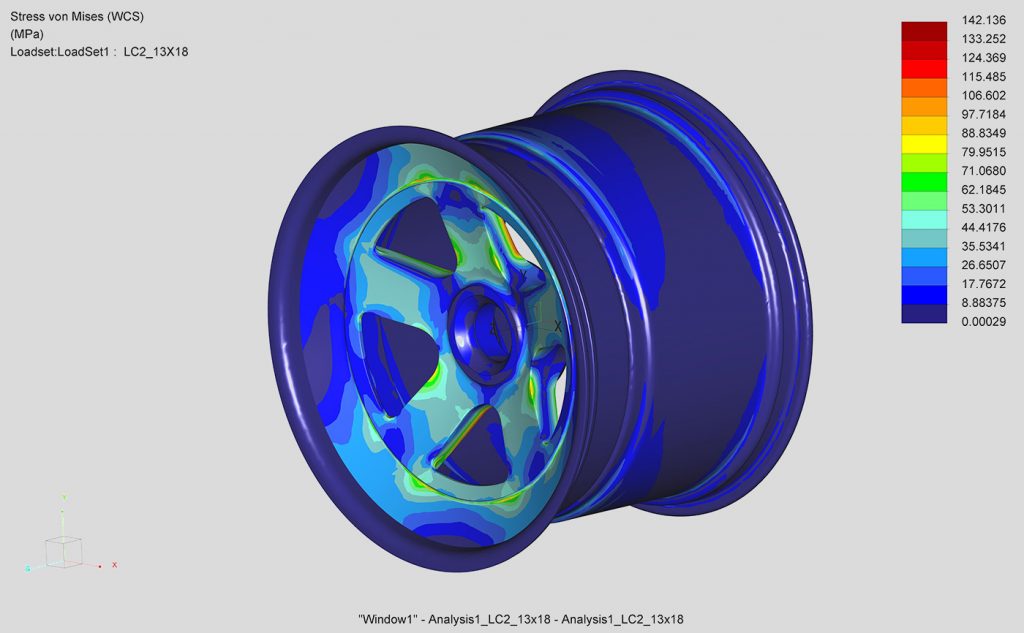

Development and Innovation:

we start the planning of the wheels using CAD-CAM programmes. Specific technologies (like FEM- Finite Element Method) allows us to give our wheels the maximum lightness. To guarantee the maximum safety in every normal use situation our products must comply with the rigours requirements imposed by the German Tüv.

RESEARCH AND TECHNOLOGY IN THE MATERIALS

we use raw alloy to always guarantee the same quality standard in the final product.

We are one of the few companies on the After-Market which uses the low pressure casting technology (this is essential for OEM wheels, i.e. wheels for the first equipment). Low pressure guarantees a more resistant product, thanks to the compactness of the metal we can obtain.

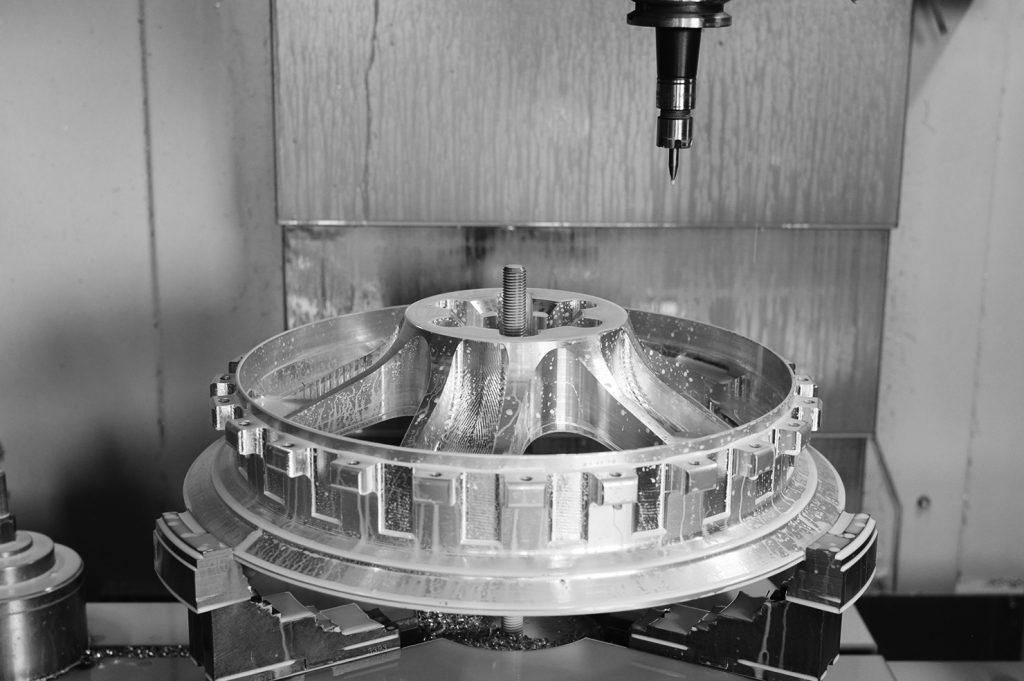

At this stage comes the numerically-controlled mechanical machining with diamond tools to obtain an high precision and an intense and inimitable bright.

CARE OF THE MINIMUM DETAIL

In every working stage: planning, model design, casting, mechanical machining, dimensional check, painting and packaging, every operation is rigorously checked to always have the same standard quality